What Is a Supplier Risk Assessment?

Let’s discuss something that’s been making headlines lately. In May 2024, Toyota Motor had to repeatedly halt production at its plant in Mexico. Local labor shortages disrupted their suppliers’ output, causing significant delays and financial losses. This resulted in an operating loss of $176 million in North America for the first quarter of the year.

This isn’t an isolated incident. During the COVID-19 pandemic, supply chains were chaotic, leading to severe disruptions. For example, the pandemic caused global supply chain shortages, impacting everything from consumer goods to industrial production. More recently, the by disrupting the supply of critical commodities like grain and energy, driving up costs and increasing global tensions.

These real-world examples highlight the critical importance of supplier risk assessment. Without a robust evaluation of potential risks from suppliers, companies can face significant operational and financial setbacks. A Deloitte survey found that 65% of procurement leaders need more visibility beyond their tier-one suppliers, underscoring the need for comprehensive supplier risk assessments.

So, what exactly is supplier risk assessment, and how can you effectively manage it? Let’s delve into the details to find out.

What is a Supplier Risk Assessment?

A supplier risk assessment is a vital process that businesses use to identify, analyze, and manage potential risks associated with their suppliers that can directly impact a company’s ability to deliver products and services efficiently and reliably.

In the past, companies focused on direct risks like supplier performance issues or unexpected disruptions. However, today’s business environment demands attention to a broader range of risks, including environmental, social, and governance (ESG) factors and cybersecurity threats. Businesses can better prepare to handle potential disruptions by thoroughly assessing these risks, ensuring smooth and resilient operations.

Moody’s Analytics reports that 70% of businesses are increasing their investments in supplier risk management, highlighting its growing importance. This surge in investment is driven by the need to prevent disruptions, comply with regulatory requirements, and sustain uninterrupted business operations.

Understanding and managing supplier risks enables companies to develop effective strategies to mitigate these risks, promoting a more resilient supply chain. This proactive approach is essential for maintaining business continuity, ensuring compliance, and upholding quality standards in the face of various challenges.

Different Types of Supplier Risks

Understanding the diverse types of supplier risks is crucial for businesses to ensure strong supplier risk management. Here’s a detailed look at each category:

- Performance Risk: This risk arises when a supplier does not meet the expected performance standards. Issues can include subpar product quality, delivery delays, or failing to provide the agreed quantity of goods. Such discrepancies can disrupt production schedules and affect customer satisfaction.

- Financial Risk: A supplier’s financial health is vital. Financial instability, such as the risk of bankruptcy or severe cash flow problems, can lead to interruptions in supply. Monitoring suppliers’ financial health helps in foreseeing and mitigating these risks.

- Operational Risk: This encompasses a supplier’s internal processes, including manufacturing techniques, labor conditions, and general efficiency. Operational inefficiencies in these areas can lead to product defects, increased costs, and ethical concerns, damaging a company’s reputation.

- Geopolitical Risk: Suppliers located in or sourcing materials from regions with political instability, regulatory upheavals, or strict trade controls can pose significant risks. These factors can lead to supply disruptions, increased costs, or complicated import/export procedures.

- Environmental, Social, and Governance (ESG) Risk: ESG factors are increasingly important in supplier risk management. Environmental concerns include pollution and waste management, social risks involving labor practices and worker safety, and governance relating to ethical management and compliance with laws. Neglect in these areas can lead to regulatory penalties, reputational damage, and operational disruptions.

- Cyber Supply Chain Risk: As businesses increasingly rely on digital processes, suppliers’ cybersecurity practices become critical. A breach in a supplier’s systems can compromise sensitive data, disrupt supply chain operations, and result in significant financial and reputational losses.

- Natural Disasters and Events Risk: Suppliers may be impacted by uncontrollable natural events such as earthquakes, floods, or pandemics. These events can halt production, destroy inventory, and obstruct logistics. Planning for such risks involves strategies like diversifying supplier locations and maintaining emergency stock reserves.

By proactively identifying these risks, companies can safeguard their supply chains from potential disruptions and ensure continuity in their operations.

Five Keys to Effective Supplier Risk Assessments

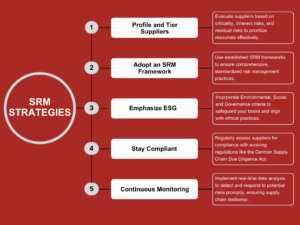

Now that we have a handle on different supplier risks, how do we tackle them effectively? Here are some strategies to consider:

- Profile and Tier Your Suppliers: Evaluate suppliers based on profile, inherent, and residual risks. Profiling involves understanding the criticality of the supplier’s products or services to your business operations. Inherent risk refers to the level of risk present before any risk mitigation measures are applied. In contrast, residual risk is the level of risk that remains after mitigation efforts are implemented. This approach helps prioritize attention and resources on the most critical suppliers.

- Align with an SRM Framework: Adopting established supplier risk management (SRM) frameworks ensures that your risk management practices are comprehensive and standardized. These frameworks offer guidelines and best practices that help identify, assess, and manage supplier risks effectively, minimizing coverage gaps and enhancing overall risk management.

- Emphasize ESG: Environmental, social, and governance (ESG) risks have become increasingly important in today’s business environment. Poor performance in these areas can lead to significant reputational damage, legal issues, and customer backlash. Incorporating ESG criteria into your supplier risk assessments helps ensure that your suppliers adhere to ethical practices, environmental sustainability, and good governance, protecting your brand and aligning with societal expectations.

- Stay Compliant with Evolving Regulations: Regulations related to supply chain management and supplier practices are continually evolving. Regularly assessing your suppliers for compliance with current and upcoming regulations, such as the German Supply Chain Due Diligence Act, is crucial. Staying compliant helps avoid legal penalties and ensures that your supply chain operates within the boundaries of the law, fostering trust and reliability.

- Continuous Monitoring: Periodic assessments are needed in the dynamic business environment. Constant monitoring of suppliers through real-time data analysis enables you to stay ahead of emerging risks. Implementing continuous monitoring solutions allows you to promptly detect and respond to potential issues, ensuring that your supply chain remains resilient and adaptable to changes.

Wrapping Up

Supplier risk assessments are essential for identifying and mitigating potential threats to the supply chain. By understanding and addressing these risks, companies can maintain continuity and resilience in their operations, ensuring consistent delivery of products and services.

At iTech GRC, an IBM OpenPages partner, we specialize in helping businesses implement comprehensive supplier risk management strategies. Our expertise ensures your supply chain is prepared for the unexpected. Contact us today to learn more about how IBM OpenPages powered by Watson.ai can help you manage supplier risks effectively.